Hydraulic tank

The second pillar of the hydraulic system is the hydraulic oil tank. As we said before, the oil tank is a place to store a certain amount of hydraulic oil. Notice that the hydraulic system is basically a closed cycle. In each closed cycle, the flow starts from the points and finally returns to the same point. Such closed cycles are also called circuits. Like an electric circuit in which the flow of electrons starts from a source such as a battery and after circulating in the circuit and producing thermal energy or lighting or... it returns to the source and this cycle repeats continuously. The hydraulic system actually works as a circuit; with the difference that instead of electrons and electricity, hydraulic oil flows in the hydraulic circuit. In a hydraulic circuit, the starting point of hydraulic fluid flow, hydraulic oil tank. Hydraulic oil returns to the tank after circulating in the circuit and doing the work by means of hydraulic actuators.

Therefore, in a hydraulic system, there should always be a constant volume of oil available.

The hydraulic circuit is similar to an electric circuit, with the difference that instead of

The electric current of the hydraulic oil flows.

Specifications of the hydraulic tank

It created a space where any change in the volume of liquid in the hydraulic circuit can be easily controlled. For example, when hydraulic jack opens, a large amount of oil enters the hydraulic circuit and the tank level goes down.

compensate for system leakage.

Considered as an always available and fully populated resource.

able to cool the heated oil returned from the circuit.

The function of the hydraulic tank

Hydraulic tank in addition to storing fluid, has other important duties as part of a hydraulic circuit. The four main functions of the hydraulic tank are as follows:

- Storing hydraulic fluid

- Heat exchanger (cooling and heating fluid)

- Sedimentation of contaminants in the fluid

- The release of air in the fluid

A common feature of all tanks

The specification of the oil tank in different hydraulic system may be different; But

Common features in all these repositories include the following 4 items:

1- Hydraulic tanks are usually made in the shape of a cube or rectangular cube.

2- In all the tanks, there is an oil filling channel that is installed on the top of the tank.

Is.

3- In the lowest part of the tank, there is an oil drain, often equipped with a Hand faucet

or a cap. This duct is used for when we want the oil in the tank

Drain and replace with new oil.

4- An oil level indicator is usually installed on the body of the tanks, which shows the amount of oil inside the tank.

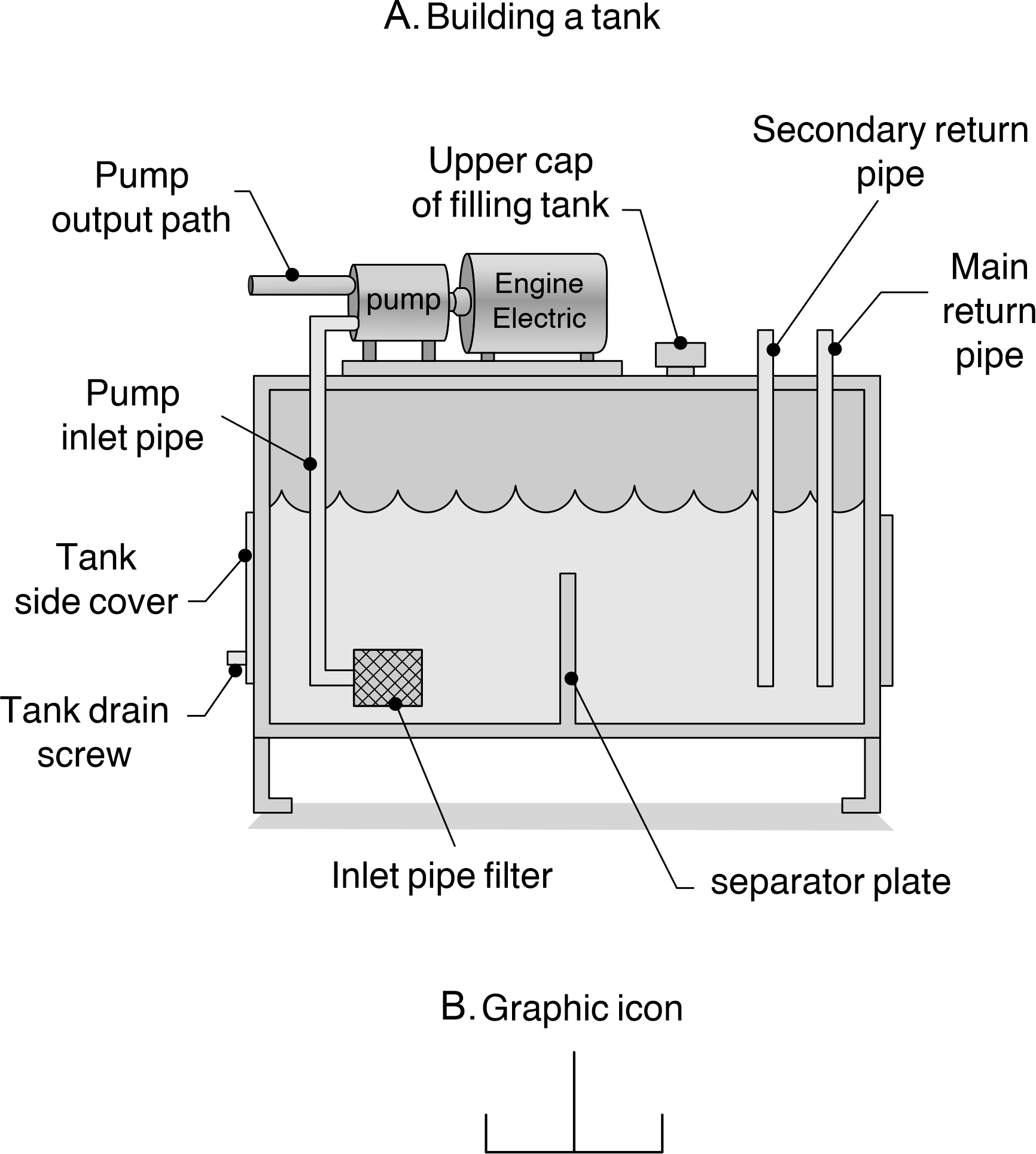

Hydraulic tank building

The different parts of a hydraulic tank and their arrangement in relation to each other are shown in the figure below:

Fluid enters the pump through a pipe. At the end of this pipe, a filter is installed to prevent pollution particles from entering the pump. Two fluid return pipes are also installed on the tank. One of these pipes is the main return pipe of the fluid from the system to the tank, and the other pipe is intended to drain the fluid from the sub-discharge paths of the parts to the tank. A filter is also installed at the end of the main return pipe. But the secondary return pipe does not have a filter because this path must have minimum resistance to the passage of fluid so that the leaks in the parts and air bubbles can be easily drained.

The size of the hydraulic tension tank

The capacity of the hydraulic tank should be such that it matches the changes in the volume of liquid in the system. Also, the size of the side surface should be designed so that they are effective in cooling the oil.

A tank with dimensions larger than the required size has disadvantages such as increasing the price, increasing the occupied space, and also requires more time to warm up in cold weather. Therefore, it will be difficult to start the device. The following methods will help you to get the right size hydraulic tank.

The minimum capacity of the hydraulic tank should be twice the flow rate of the pump. This size is the minimum possible and the capacity should not be less than this value because it may not be enough for volume changes in the system.

The capacity of the hydraulic tank should be 3 to 4 times the flow rate of the pump per minute. This amount is very high for use in the automotive industry.

The capacity of the tank should be 2 to 15 liters per engine power. This type of tank is used when very high pressure is required. In this case, the capacity of the tank will be large.

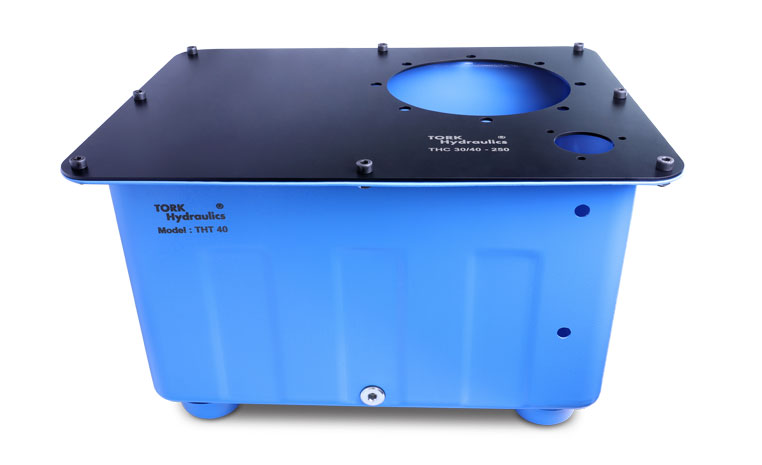

30-liter and 40-liter tension tanks are produced and supplied by our company.

30 liter tension tank, hydraulic crack - THT30

40 liter tension tank, hydraulic crack - THT40

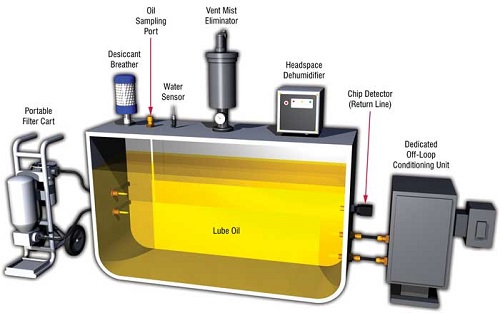

The shape and design of the hydraulic tank

An oil inlet valve and an air valve should be installed on the tank. Usually, on tanks, these two valves are combined with each other, and an air outlet valve is also considered on the tank. The combination of the two causes the tank to fill slowly when filling the hydraulic tank, but the air outlet valve causes the tank to fill more quickly. In this way, some dust will enter the system when filling the tank. In addition, you can remove the air filter cap on the tank to fill the tank quickly. In this case, some dust will still enter the system. It is better to consider a special liquid inlet valve on the tank, which has a special filter and coupling. In this case, all the liquid will pass through the filter and be cleaned.

In highly polluted environments, you can protect the liquid well by using a fully sealed hydraulic tank. In addition, by using special separators, the oil can be protected in different level changes. In this case, an air bag is placed on the surface of the oil in such a way that when the liquid level changes, the air is directed in or out.

The application of flexible separators is limited and they are used only in cases where the circuits containing the hydraulic motor have small changes in the hydraulic fluid level. In this situation, a special breathing valve is used. In this case, the pressure drop inside the tank is 0.03 bar, air can enter the tank through a filter with a hole diameter of 25 micrometers. Therefore, it is necessary to take necessary measures to prevent pump failure caused by cavitation. As a result, it exerts up to 0.3 bar pressure on the tank, and in case of an increase in pressure, the pressure relief valve is opened and the excess pressure is discharged.

The suction line of the pump should be equipped with a suitable strainer with the correct size. This strainer, while absorbing waste materials suspended in tank oil, causes good flow distribution in the pipe and should be installed at a distance of 75 mm from the bottom of the tank. The distance of the upper surface of the filter from the lowest possible level of oil in the tank should be 150 mm to prevent the entry of air and the splashing of water resulting from pouring oil into the tank.

Related products